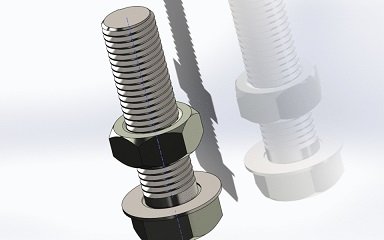

Threads are the tiny grooves spiraled around bolts and nuts that help them join together snugly. Thread sizing might seem like a labyrinth of numbers and symbols, but it’s crucial for finding the right match between bolts and nuts. Let’s unravel this mystery step by step.

Basics of Threads

Threads are the intricate grooves or ridges spiraled around bolts and nuts that allow them to join together securely. They are primarily characterized by two key measurements: diameter and pitch.

Diameter: The diameter refers to the width of the threaded part of a bolt or the inner diameter of a nut. It’s akin to measuring a circle straight through its center.

Pitch: This measurement signifies the distance between individual threads. Think of it as the spacing between steps on a staircase.

Standard Sizing Systems

Unified Thread Standard (UTS)

In the Unified Thread Standard, thread sizes are often denoted by fractions or numbers followed by a hyphen and another number. For instance, you might encounter specifications like ¼-20 or 5/16-18.

¼-20: This indicates a bolt with a diameter of ¼ inches and 20 threads within a one-inch length.

5/16-18: This denotes a bolt with a diameter of 5/16 inches and 18 threads in one inch.

Metric Thread Standard

Metric thread standards use millimeters for measurement and refer to the diameter and pitch. For instance, M8x1.25 signifies:

M8: An 8mm diameter bolt.

1.25: Signifying a pitch of 1.25mm, the distance between individual threads.

Identifying Bolt Threads

Measuring Diameter

To determine the diameter of a bolt, measure the widest part of the bolt’s threads using a caliper or ruler. This measurement represents the bolt’s diameter.

Determining Pitch

To establish the pitch of a bolt’s threads, place a ruler against the threads and count the number of peaks that align within a one-inch span. This count provides the number of threads per inch (TPI) and aids in determining the pitch.

Choosing the Right Nut

Selecting the appropriate nut involves ensuring compatibility with the bolt’s specifications. This includes matching the nut’s size (diameter and pitch) to that of the bolt for a secure and snug fit.

Thread Engagement

Thread engagement refers to the depth of threads that overlap when a bolt and nut are joined. Adequate thread engagement ensures a strong and reliable connection between the components.

Importance of Thread Compatibility

Using mismatched threads can lead to loose connections, compromising structural integrity. Verifying thread compatibility is crucial to prevent accidents and ensure a sturdy assembly.

Common Thread Problems

Stripped Threads

Stripped threads occur when the threads are damaged, making it challenging for bolts and nuts to join securely. Avoid over-tightening to prevent stripping.

Cross-threading

Cross-threading happens when the threads of the bolt and nut are misaligned during assembly, resulting in damage. Properly align both components before threading to avoid this issue.

Conclusion

Understanding thread sizing—comprising diameter, pitch, and ensuring compatibility—ensures a seamless fit between bolts and nuts. Accurate measurement and prioritizing compatibility are essential to achieve secure and reliable connections in any project.

In summary, while thread sizing might appear complex, grasping the fundamentals—diameter, pitch, and matching sizes—facilitates selecting the right components for any project, guaranteeing strong and durable connections between bolts and nuts.