Automatic filling machines can use a number of different filling principles to get the product into the bottle. Each filling principle has its own unique benefits or advantages. While more than one type of liquid fill may work for a given project, each project will have an ideal filling machine, or filling principle, to complete the job.

Overflow filling machine

The principle behind the overflow filling machine is the ability to fill a specific level in each bottle, even if there are small discrepancies in the individual bottles. This can filling machine offers an obvious aesthetic value to products that are packaged in transparent containers, such as bottled water and window cleaners. As with all filling machines discussed in this article, overflow fillers can be manufactured to meet almost any production demand, such as tabletop, semi-automatic, or fully automatic bottle fillers.

The overflowing filler is likely to be the ideal filling machine for products packaged in clear containers. Thus, the machine will be limited by the viscosity of the product. Overflow filters work with thin to medium viscosity products and even product permeability. Special nozzles allow the overflow of the filling bottle to fill each bottle to one level, despite the slight variation within the internal volume of the container. The products are in clear containers, though and the filling step leads to a good shelf attraction, adding aesthetic value to the filling design.

Gravity filling machine

Gravity filling machines allow easy filling of free-flowing products using a tank mounted over the filling heads and time-based volume filling. Gravity fill machines can use a number of different filling nozzles and may include options such as dive heads, foam control, and other additional manual adjustment for each project.

Gravity fill machine is good for free products that need to fill time. These machines can use a variety of filling nozzles depending on the product and the vessel being filled. Unlike overflowing filler, gravity filling machines do not use refilling or recirculation system and do not require professional nozzles. For these reasons, the gravity filler provides an economical solution to low-viscosity, free-flowing products.

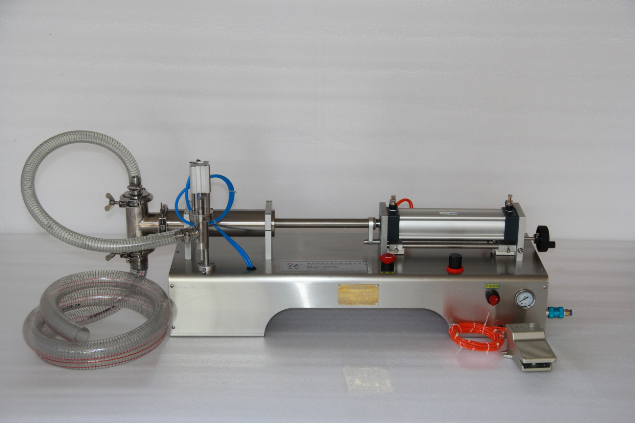

Piston filling machine

Piston filling machines also use volumetric filling principle, but allow filling of solid products such as pasta, jam and jellies. Generally speaking, the piston returns to the specified position for each filling time, allowing the same amount of product in the cylinder with each stroke. As the piston re-enters the cylinder, the device is pushed through the mouth or nose into the waiting vessel.

Because the amount of fluid in the piston filler will not change, this fluid filling provides a more precise volumetric filling. While it can handle pieces like a filling pump, the piston filler can also work with large chunks in products such as tomato paste or jam and jellies with fruit pieces.

Pump filling machine

Pipe filling machines provide flexible handling not only thinner products, but higher viscosity products as well. The pumps used in these water filters will be adapted to the project on a one-to-one basis, allowing the sewing machine to be built with a pump that is well suited for each project. Filters can also handle interior products such as dressing salads or sand soap. Various nozzles can also be used in filling the pump to suit the actual application built machine.

Machines that use a pump filling principle can also be ideal for thick, bulky viscous products. The type of pump used will depend on the product and filling completion, with many options available. For example, a gear pump can be used to move a device depending on the time or rotation of the gear (pulse based). The peristaltic pump uses rollers that allow the product to flow without contact with the components of the pump, only with a tube, which makes this pump ideal for chemical processes and other food or fragrances.

Selecting the exact filling equipment can be measured as a result of the success and design of the packing line and ultimately the bottom line for any package. To learn more about any of the different principles of filling out or which ones work best for a given program, contact Npack today.